“In Rwanda, 18 percent of girls and women missed out on school and work [in 2016] because they could not afford to buy menstrual pads. Apart from the personal injustice and the larger issues of health and dignity, these absences are a potential GDP loss of $215 per women every year — a total of $115 million in Rwanda. It is estimated that 10 percent of African school-age girls do not attend school during menstruation. Missing four days every month is a significant loss in educational time…”

Sustainable Health Enterprises

Designing plastic out of the packaging experience.

Challenge

Many women around the world use sanitary napkins every month when they have their period. Without thinking, they wrap the used pad in the plastic wrapper and toss it into the trash, and go back to their lives with barely any interruption. However, when bathroom trash cans are non-existent and pads are thrown down the latrine, the plastic ends up polluting the farming fertilizer stream.

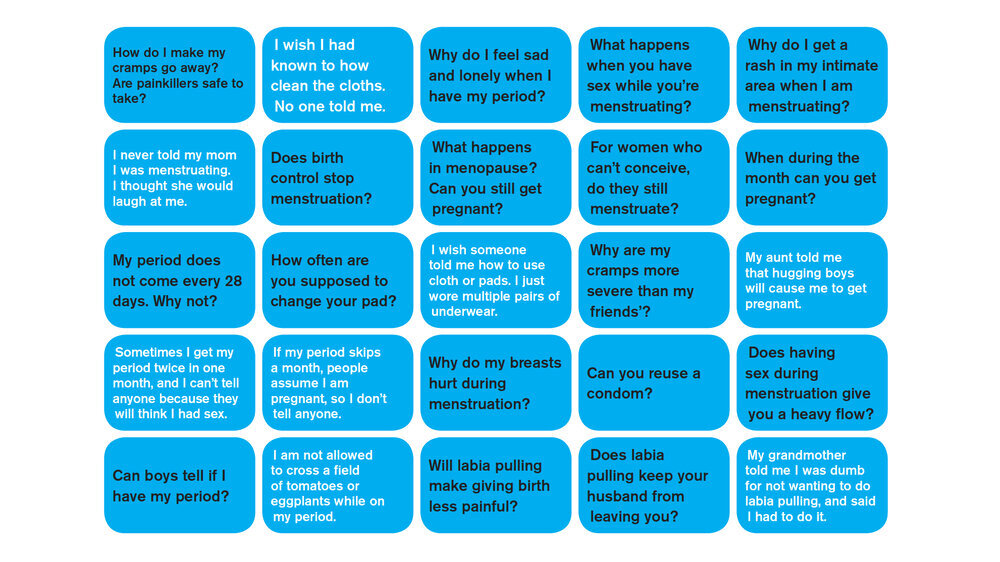

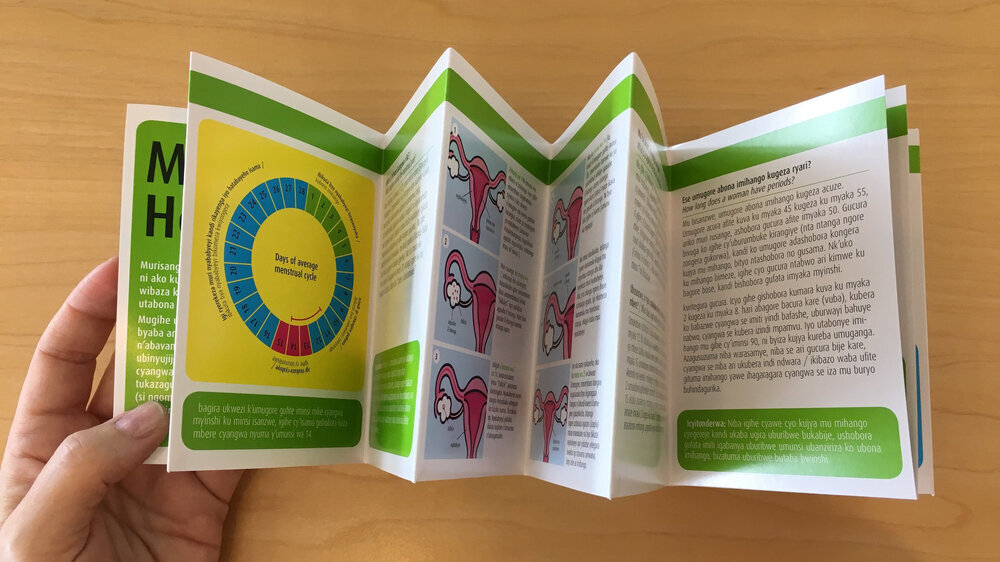

We were asked to help reduce the amount of plastic that was being used on SHE’s go! sanitary napkin packaging in order to better comply with Rwanda’s (at the time, forthcoming) 2019 law prohibiting the manufacturing, importation, use and sale of single-use plastic items. As part of the new packaging, we were also asked to think about how we could include an educational component for girls and women to better under their bodies and reproductive health.

Solution

According to Be Kind Magazine, “The average sanitary pad is made from 90 percent plastic — that’s the equivalent of four single-use carrier bags.” Even if a woman uses a paper bag to bring home a 16-pack of pads, she is still actually purchasing 64 single-use bags in the form of her individually wrapped napkins.

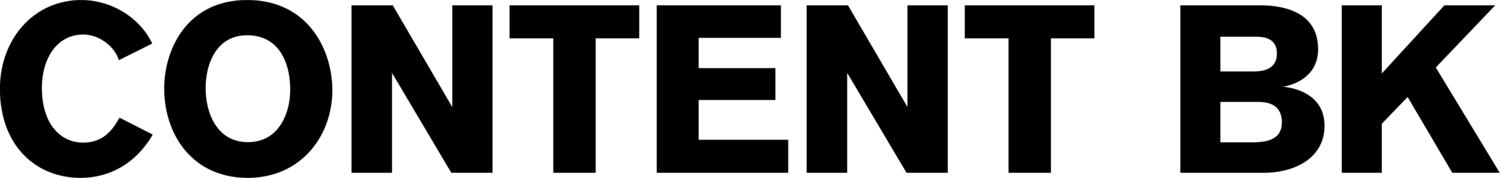

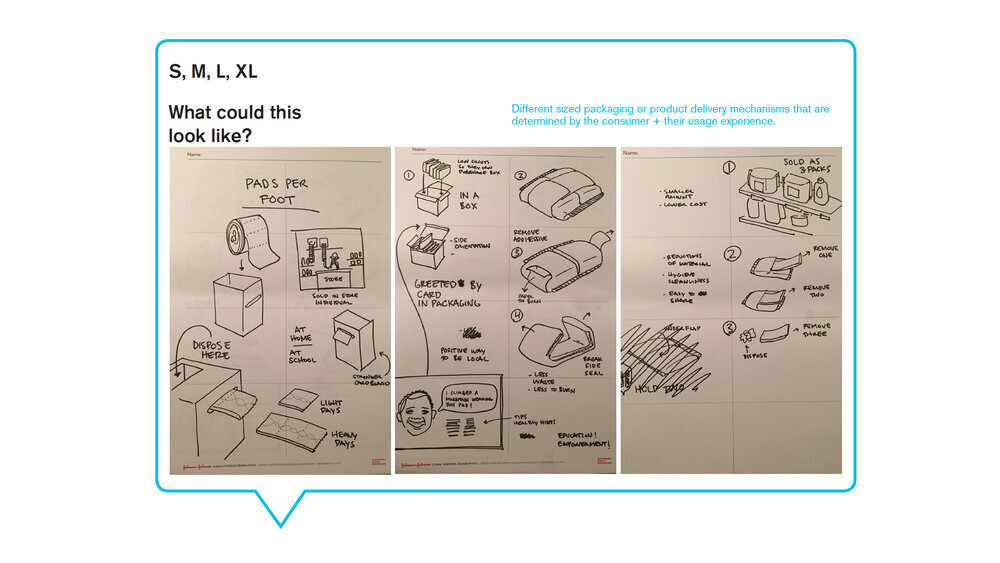

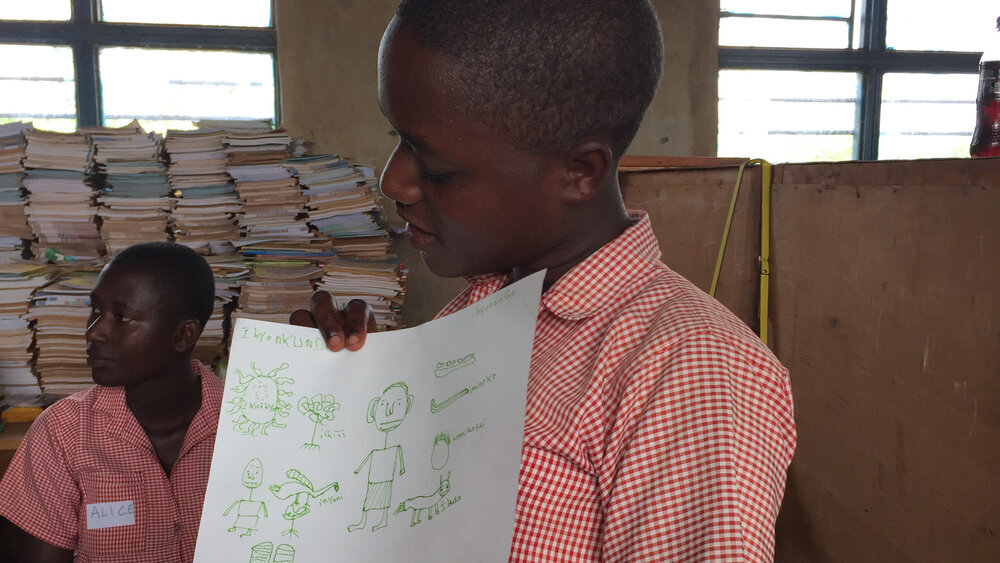

Working together with the team at SHE, we led a series of design workshops to ideate concepts around what more sustainable packaging and educational health experiences could look like. It was an iterative process where we worked with designers at Johnson & Johnson’s Design Office, as well as students at a handful of middle schools in Eastern Rwanda. For the girls in Rwanda, it was the first time that they had ever been asked to participate in conversations where people wanted their opinions and ideas on how to shape their own futures.

Results

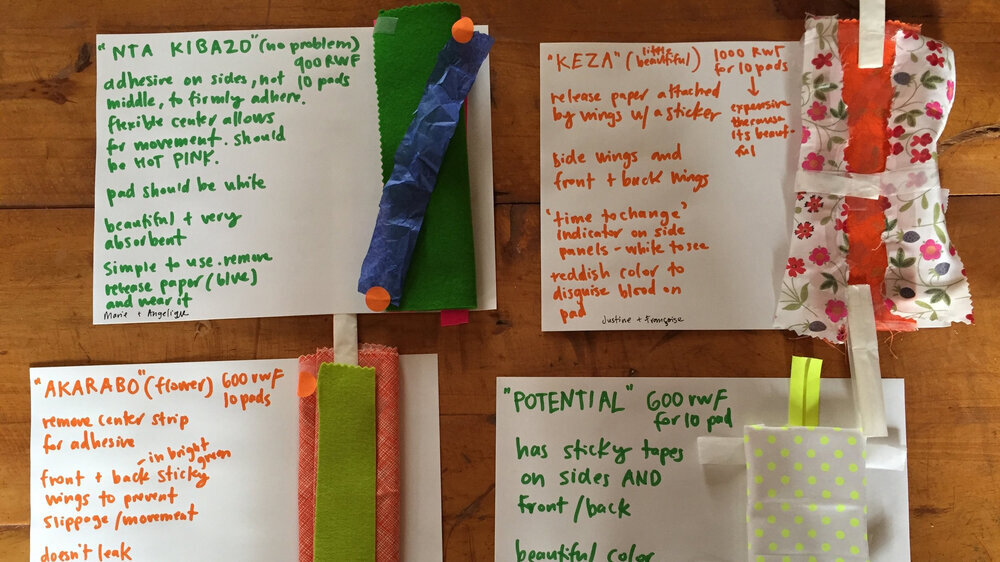

For the last phase of the project, we developed a final prototype based on the refined concept, and tested in situ with consumers.

We received a grant from Johnson & Johnson's 2016 Sustainability Accelerator Grants Challenge, which afforded us the opportunity to develop the materials for a packaging pilot. Pilot materials included an educational brochure, bulk packaging for kiosks that contained 50 pads per box sold as singles, and a smaller 3 count package of pads.